Masonry Performance

Evaluating the performance of a building envelope requires the right questions to be asked of the constituent materials. Highbridge can help determine those questions and has the tools to provide effective answers.

Our expertise in masonry materials and performance means that Highbridge is always equipped to support a design team engaged in building envelope investigations. Understanding performance of masonry assemblies means considering the interactions of several materials acting compatibly. Laboratory testing is no different. We work closely with architects, engineers, conservators, and NDT field personnel to help design testing programs that consider the assembly as more than just its individual parts.

Highbridge offers the following laboratory services for masonry investigations

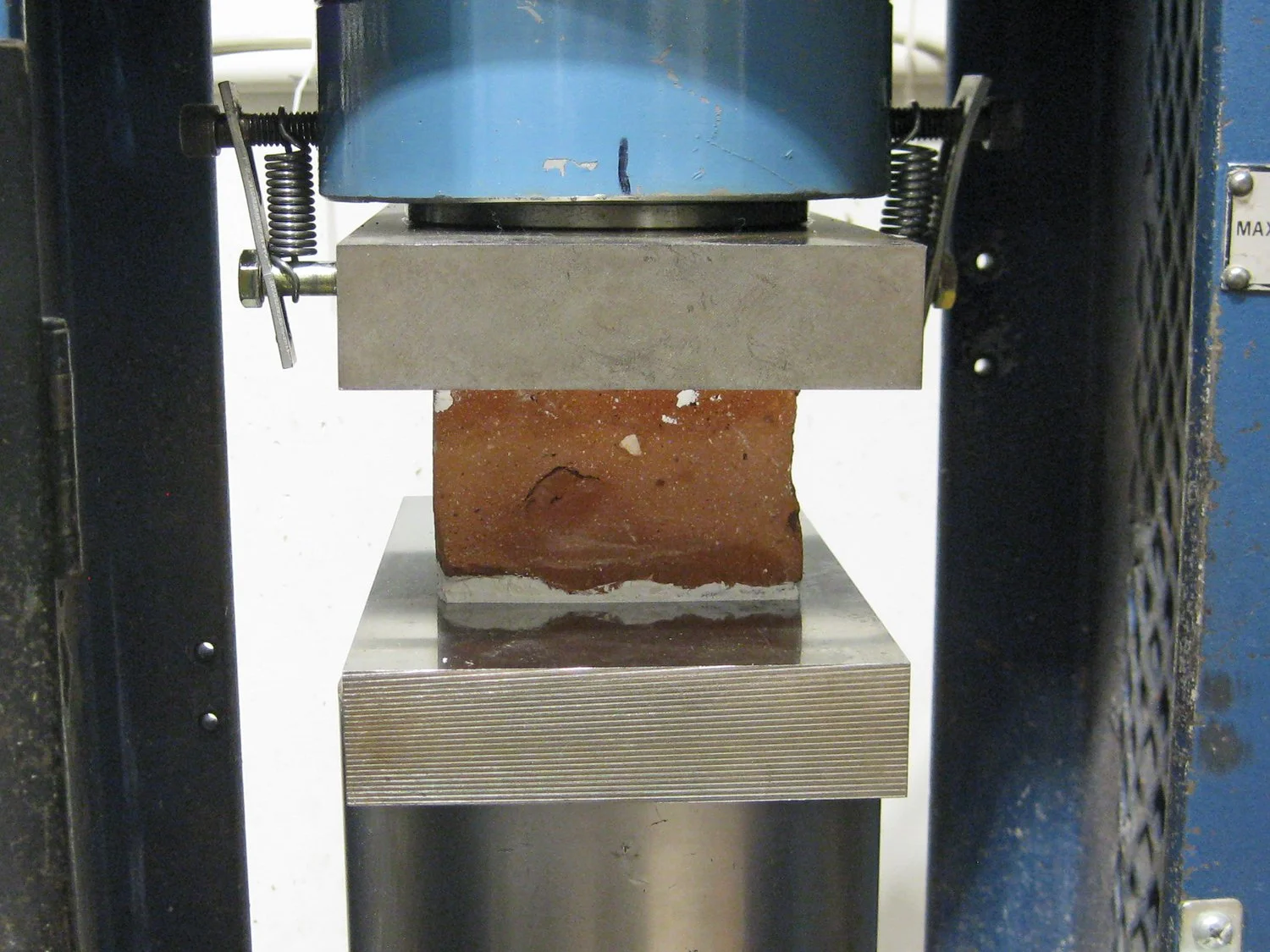

Mechanical properties of masonry units.

Determination of moisture transport values including vapor permeability, capillarity, and sorptivity.

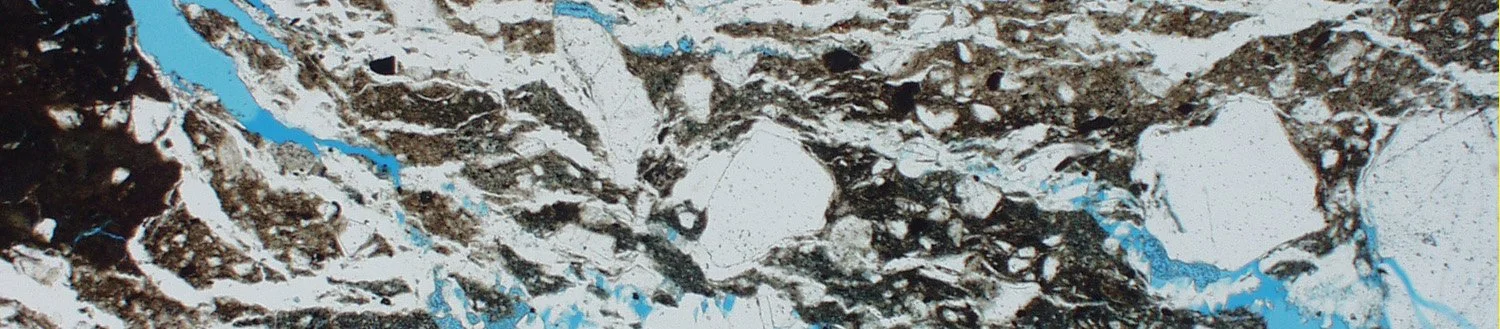

Microstructural and chemical characterization of masonry materials

Investigation of decay mechanisms in historical masonry.

Identification and distribution of salt contaminants

Comparative testing of candidate materials for repair or replacement.

Measurement of accurate input values for hygrothermal models.

Investigation of construction defects and root cause assessments of material failure.

Our clients use our services for their existing condition surveys of older buildings and the forensic evaluation of new construction failures. We use standardized and custom-designed laboratory methods to evaluate brick, stone, terra cotta, block, cast stone, mortar, and stucco.