Highbridge brings laboratory expertise to historical and modern masonry and concrete investigations.

-

Our staff specializes in petrography and chemical analysis of concrete, mortar, building stone and associated materials. We also perform a wide variety of specialty tests focused on mechanical and hygrothermal properties, and durability assessment.

-

Analytical support for

Building envelope studies

Historic preservation work

Existing condition surveys

Failure analysis

Hygrothermal assessments

Featured topics

-

Historical mortar analysis

Highbridge is perhaps best known for our expertise in historical mortars. Our analysis identifies original materials, estimates proportions, and assesses performance characteristics.

-

Building stone evaluation

Laboratory testing can measure performance characteristics and durability of existing stone or new production material.

-

Freeze-thaw testing

Standardized and custom tests to evaluate the performance of stone, concrete, cast stone, brick, and more.

-

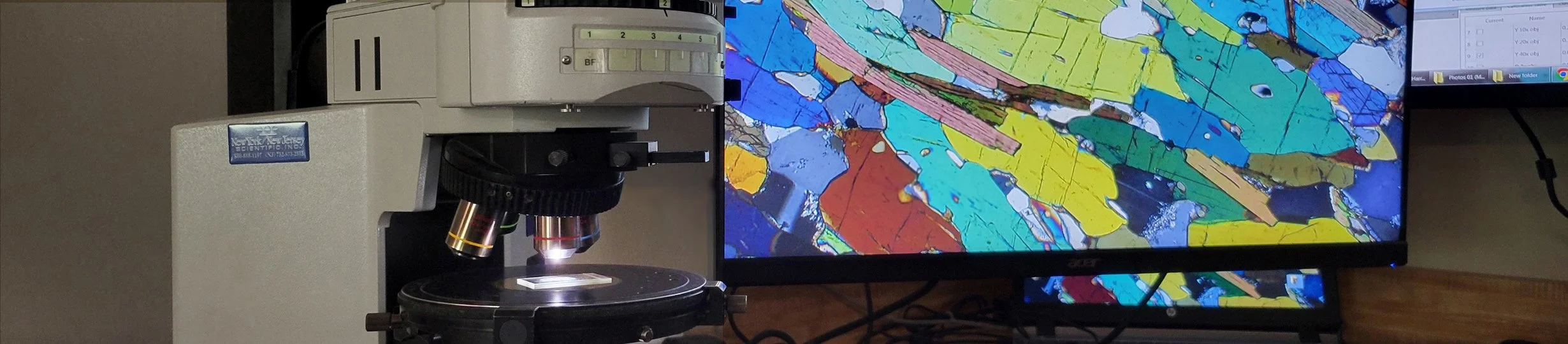

Concrete petrography

Petrographers use microscopy to understand concrete performance, deterioration, and durability.

-

Masonry performance

Tailor-made testing programs to support on-site masonry investigations.

-

Highbridge as a classroom

Hosting students and professional alike to help demystify materials science.